- Care, Quality, Style, Trend

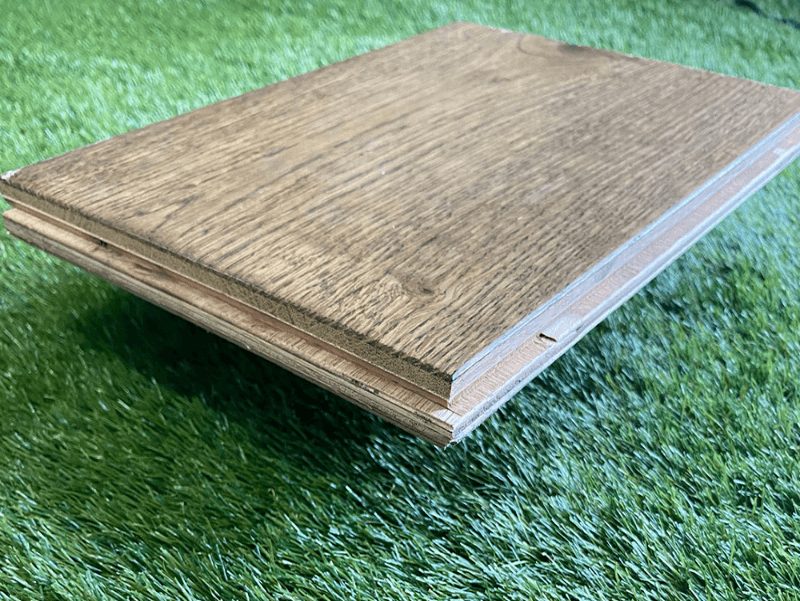

Engineered Wood: Innovations, Benefits, and Sustainability

Details

In the realm of construction and manufacturing, engineered wood has emerged as a versatile and sustainable alternative to traditional solid wood. This innovative material, crafted from wood fibers, particles, or veneers bonded together with adhesives, offers a plethora of advantages that cater to both environmental concerns and functional requirements in various applications. Evolution of Engineered Wood Engineered wood represents a significant evolution from solid wood products. Historically, solid wood has been the primary material for construction and furniture manufacturing. However, limitations such as size availability, dimensional stability, and environmental impact prompted the development of engineered wood products. The transition from solid wood to engineered wood began with the advent of plywood and has since expanded to include oriented strand board (OSB), particleboard, and medium-density fiberboard (MDF). Innovations Driving Change The development of engineered wood products has been driven by innovations in manufacturing processes and material sciences. Modern technologies allow for precise control over the composition and structure of engineered wood, enhancing its performance characteristics. For instance, cross-laminated timber (CLT) and glued laminated timber (glulam) are engineered wood products that offer exceptional strength and structural stability, making them ideal for tall buildings and large-scale construction projects. Benefits of Engineered Wood 1. Sustainability Engineered wood is celebrated for its sustainability credentials. By utilizing wood fibers efficiently and incorporating recycled materials, engineered wood minimizes waste and reduces environmental impact. Moreover, sustainable forestry practices and certifications such as Forest Stewardship Council (FSC) ensure responsible sourcing of raw materials, contributing to forest conservation efforts globally. 2. Versatility One of the key benefits of engineered wood lies in its versatility. It can be tailored to meet specific performance requirements for different applications. For example, OSB is prized for its strength and dimensional stability, making it suitable for sheathing and subflooring in construction. In contrast, MDF is valued for its smooth finish and uniform density, making it ideal for furniture and interior applications. 3. Cost-effectiveness Engineered wood often proves more cost-effective than solid wood due to its manufacturing efficiency and availability. The ability to use smaller and younger trees in its production also contributes to lower costs while preserving older trees for biodiversity and carbon sequestration. 4. Performance Engineered wood products exhibit superior performance characteristics compared to solid wood in many applications. They are less prone to warping, cracking, and splitting, offering enhanced durability and reliability. Additionally, engineered wood’s dimensional stability reduces the risk of expansion and contraction due to changes in humidity and temperature, ensuring long-term structural integrity. Sustainability Considerations The sustainability of engineered wood extends beyond its composition to include its life cycle and end-of-life considerations. By choosing engineered wood products with certifications like FSC, builders and consumers can support sustainable forestry practices and reduce environmental impact. Furthermore, engineered wood can be recycled and repurposed at the end of its life, contributing to a circular economy approach to materials management. Future Outlook Looking ahead, the future of engineered wood looks promising with ongoing research and development aimed at further enhancing its properties and expanding its applications. Advances in adhesive technologies, composite materials, and digital manufacturing techniques are expected to unlock new possibilities for engineered wood in architecture, furniture design, and beyond. As global efforts intensify to combat climate change and promote sustainable development, engineered wood stands poised to play a pivotal role in building a greener and more resilient future. Conclusion Engineered wood represents a revolutionary approach to sustainable building materials, offering a blend of innovation, performance, and environmental stewardship. With its diverse applications, from residential construction to commercial projects, engineered wood continues to redefine possibilities in modern design and construction. Embracing this versatile material not only meets the demands of today’s construction industry but also contributes to a more sustainable and environmentally responsible future. In summary, engineered wood is not just a product but a testament to human ingenuity and our commitment to balancing innovation with environmental stewardship in the pursuit of sustainable development.